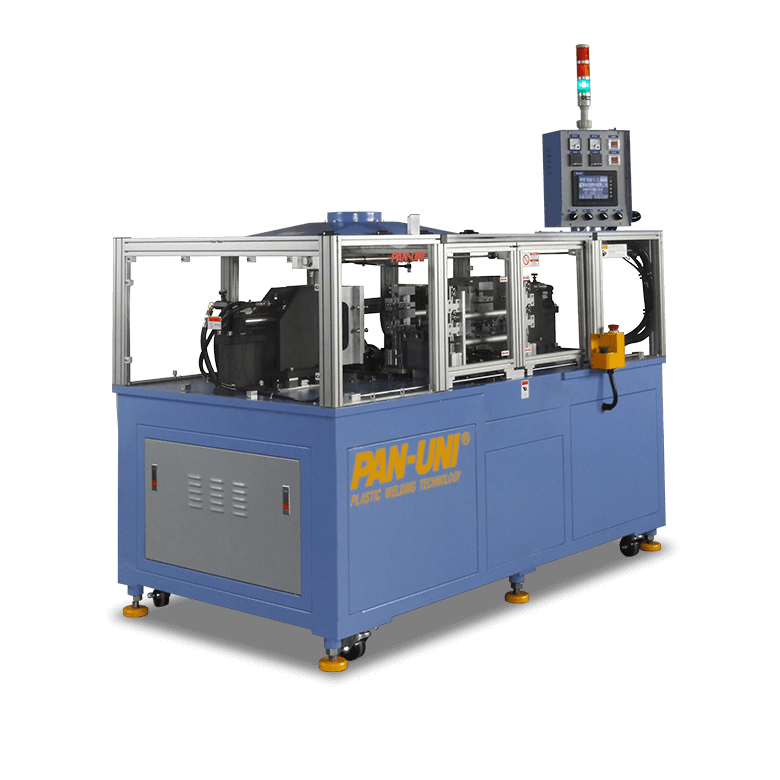

Hot Plate Welding Machine

PU-MH850L-D

PU-MH850L-D It adopts horizontal design, heat-combined processing for longer workpieces, simultaneous processing of both head and tail at the same time, which greatly shortens the processing waiting time, and can accurately meet customer requirements for high-precision workpieces.

The movable door or safety grating can be selected according to customer needs to ensure the safety of the staff.

Application: Double-end synchronous fusion processing of solar panels/PCB washing machine wafer boats (carriers) for PP, POM, nylon, etc.

- Japan FUJI 5.7” HMI.

- MITSUBISHI PLC controller.

- Japan FUJI PID thermostatic controller, SSR non-contact switch. Micro-temperature compensation ±1℃.

- Temperature difference, pressure difference electronic protector.

- End to end multi-point sync welding.

- The entire machine uses NC precision processed parts.

- Linear slide motion device. (Servo drive or pneumatic circuit transmission optional)

- Uses strong U shape chassis, aluminum extrusion and environmentally friendly powder coating for machine outward appearance.

- Abnormal operation computer monitors circuit function, pneumatic pressure and electrical temperature fool proof capability.

- Operation gate, security light curtain. (Optional)

- Series is CE safety specification certified. (Optional)

| Product Specification | |

|---|---|

| Model | PU-MH850L-D |

| Size | L1850×W1010×H1830mm |

| Weight | 1100kg |

| Pneumatic | 6kgf/cm2/30ℓ/1minute |

| Hydraulic | 50kgf/cm2 |

| Capatity | 30-50Sec./1Cycle (Not include manual placement) |

| Available | PP, POM, Nylon solar panel/PCB cleaning machine (Carrier) end to end sync welding. |

- Japan FUJI 5.7” HMI.

- MITSUBISHI PLC controller.

- Japan FUJI PID thermostatic controller, SSR non-contact switch. Micro-temperature compensation ±1℃.

- Temperature difference, pressure difference electronic protector.

- End to end multi-point sync welding.

- The entire machine uses NC precision processed parts.

- Linear slide motion device. (Servo drive or pneumatic circuit transmission optional)

- Uses strong U shape chassis, aluminum extrusion and environmentally friendly powder coating for machine outward appearance.

- Abnormal operation computer monitors circuit function, pneumatic pressure and electrical temperature fool proof capability.

- Operation gate, security light curtain. (Optional)

- Series is CE safety specification certified. (Optional)