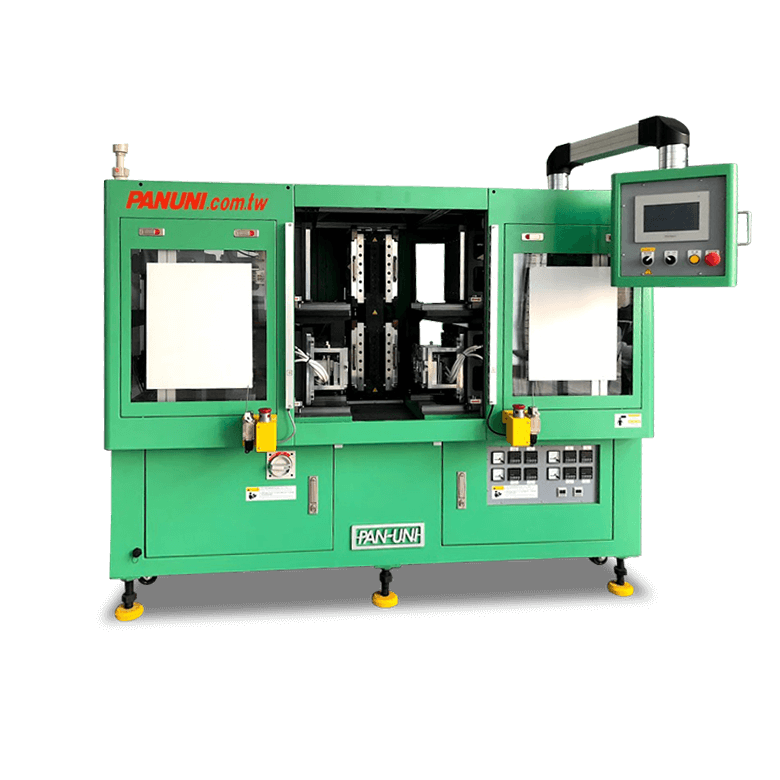

Hot Plate Welding Machine

Hot plate welding machine PU-MH1800L is specially designed for workpieces with internal pressure test requirements. The heating power and mold size can be set according to different workpiece sizes to realize a variety of plastic workpiece welding, simple operation, high production efficiency, etc., after welding, it can meet the requirements of watertight and airtight, suitable for welding of thermoplastic plastic parts of various shapes, sizes and materials. This equipment is servo-driven for the whole machine, which can perform welding processing more accurately. It can be used in automobile ABS brake oil cans or more precise processing parts, and can achieve strict certification.

Suitable for PE, PP, nylon, ABS, acrylic, POM and other large welding surfaces and the requirements of internal pressure testing.

- Series utilize HMI controller.

- Series uses PLC controller.

- PID thermostatic controller, SSR non-contact switch. Micro-temperature compensation ±1℃.

- Temperature difference, pressure difference electronic protector.

- The entire machine uses NC precision processed parts.

- Working kit made with bearing steel SUJ2 (RHC62±2) to ensure precision, stability and long operational lifespan.

- Modular mold changing design.

- Strong U shape chassis. Extremely stable during operation with CNC sheet metal and environmentally friendly powder coating.

- Abnormal operation computer monitors circuit function, pneumatic pressure and electrical temperature fool proof capability.

- Hydraulic circuitry utilizes heating and High/Low speed control while jointing. This makes a cleaner and stronger weld joint.

- Operation gate, security light curtain. (Optional)

- Series is CE safety specification certified. (Optional)

| Product Specification | |

|---|---|

| Model | PU-MH1800L |

| Size | L2450×W1400×H1780mm |

| Weight | 1350kg |

| Power | Servo actuation |

| Pneumatic | 6kgf/cm2/50ℓ/1minute |

| Capatity | 30-50Sec./2Pcs. (Not include manual placement) |

| Available | PE, PP, Nylon, ABS, Acrylic, POM etc. Large welding surface and must withstand internal pressure test requirements. |

- Series utilize HMI controller.

- Series uses PLC controller.

- PID thermostatic controller, SSR non-contact switch. Micro-temperature compensation ±1℃.

- Temperature difference, pressure difference electronic protector.

- The entire machine uses NC precision processed parts.

- Working kit made with bearing steel SUJ2 (RHC62±2) to ensure precision, stability and long operational lifespan.

- Modular mold changing design.

- Strong U shape chassis. Extremely stable during operation with CNC sheet metal and environmentally friendly powder coating.

- Abnormal operation computer monitors circuit function, pneumatic pressure and electrical temperature fool proof capability.

- Hydraulic circuitry utilizes heating and High/Low speed control while jointing. This makes a cleaner and stronger weld joint.

- Operation gate, security light curtain. (Optional)

- Series is CE safety specification certified. (Optional)