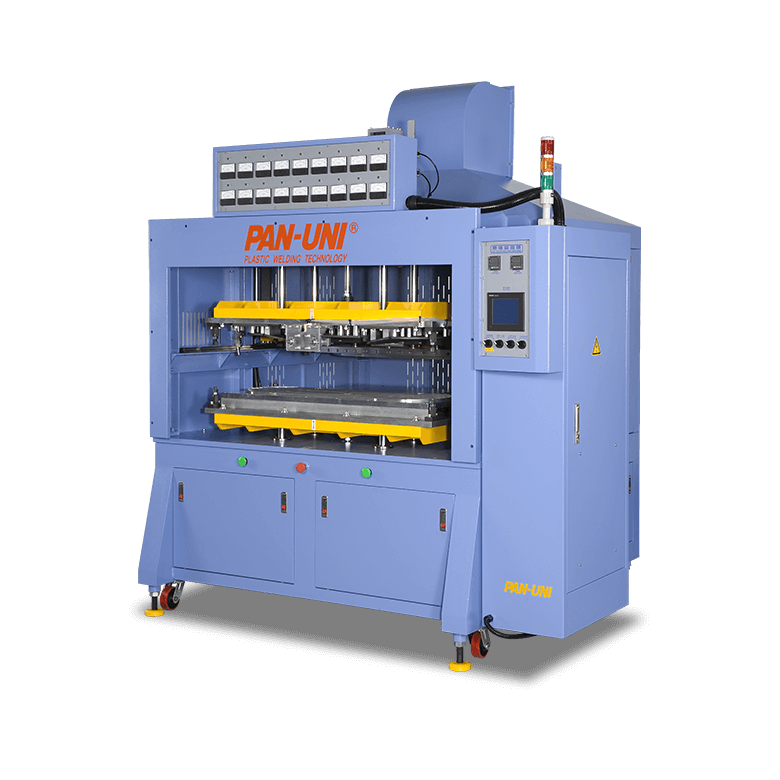

Hot Plate Welding Machine

PU-MH1650LW

PAN-UNI Hydraulic system hot plate welding machine PU-MH1650LW has the characteristics of durability, long service life and easy maintenance. It can maintain its superior performance even after long-term operation. It is specially designed for thermal bonding of large workpieces. It is used in large-scale automobile auxiliary tank or other car radiator and containers, rhythm pedals or products with large length and width dimensions.

Applicable: PE, PP, nylon, ABS, acrylic, POM and other large welding surfaces are required to withstand internal pressure testing.

- Series utilize HMI controller.

- Series uses PLC controller.

- PID thermostatic controller, SSR non-contact switch. Micro-temperature compensation ±1℃.

- Temperature difference, pressure difference electronic protector.

- The entire machine uses NC precision processed parts.

- Working kit made with bearing steel SUJ2(RHC62±2) to ensure precision, stability and long operational lifespan.

- Modular mold changing design.

- Strong U shape chassis. Extremely stable during operation with CNC sheet metal and environmentally friendly powder coating.

- Abnormal operation computer monitors circuit function, pneumatic pressure and electrical temperature fool proof capability.

- Hydraulic circuitry utilizes heating and High/Low speed control while jointing. This makes a cleaner and stronger weld joint.

- Operation gate, security light curtain. (Optional)

- Series is CE safety specification certified. (Optional)

| Product Specification | |

|---|---|

| Model | PU-MH1650LW |

| Size | L1850×W1700×H2320mm |

| Weight | 1100kg |

| Pneumatic | 6kgf/cm2/50ℓ/1minute |

| Hydraulic | 50kgf/cm2 |

| Capatity | 20-50Sec./1Mold (Not include manual placement) |

| Available | PE, PP, Nylon, ABS, Acrylic, POM etc. Large welding surface and must withstand internal pressure test requirements. |

- Series utilize HMI controller.

- Series uses PLC controller.

- PID thermostatic controller, SSR non-contact switch. Micro-temperature compensation ±1℃.

- Temperature difference, pressure difference electronic protector.

- The entire machine uses NC precision processed parts.

- Working kit made with bearing steel SUJ2(RHC62±2) to ensure precision, stability and long operational lifespan.

- Modular mold changing design.

- Strong U shape chassis. Extremely stable during operation with CNC sheet metal and environmentally friendly powder coating.

- Abnormal operation computer monitors circuit function, pneumatic pressure and electrical temperature fool proof capability.

- Hydraulic circuitry utilizes heating and High/Low speed control while jointing. This makes a cleaner and stronger weld joint.

- Operation gate, security light curtain. (Optional)

- Series is CE safety specification certified. (Optional)