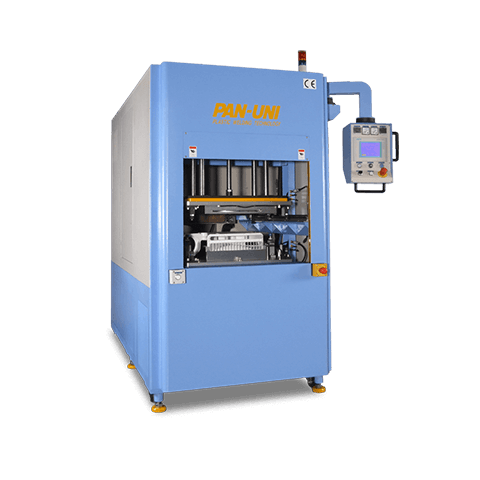

Hot Plate Welding Machine

PU-MH1000CE

PU-MH1000CE The working principle of the hot plate welding machine is to put the workpiece into the upper and lower hot plate molds, and use the hot plate mold to advance and retreat for heating action. The temperature of the hot plate mold can be adjusted according to the workpiece, and it has a protection function beyond ±5°C. With quick mold change design, suitable for flat or curved surface processing components, simple operation.

Application: PE, PP, nylon, ABS, acrylic, POM, etc., such as car tail lights, turn signal lights, car radiator, containers.

- Series utilize HMI controller.

- Series uses PLC controller.

- PID thermostatic controller, SSR non-contact switch. Micro-temperature compensation ±1℃.

- Temperature difference, pressure difference electronic protector.

- The entire machine uses NC precision processed parts.

- Working kit made with bearing steel SUJ2(RHC62±2) to ensure precision, stability and long operational lifespan.

- Modular mold changing design.

- Strong U shape chassis. Extremely stable during operation with CNC sheet metal and environmentally friendly powder coating.

- Abnormal operation computer monitors circuit function, pneumatic pressure and electrical temperature fool proof capability.

- Hydraulic circuitry utilizes heating and High/Low speed control while jointing. This makes a cleaner and stronger weld joint.

- Operation gate, security light curtain. (Optional)

- Series is CE safety specification certified. (Optional)

| Product Specification | |

|---|---|

| Model | PU-MH1000CE |

| Size | L2002×W1615×H2159mm |

| Weight | 850kg |

| Pneumatic | 6kgf/cm2/50ℓ/1minute |

| Hydraulic | 50kgf/cm2 |

| Capatity | 20-40Sec./1Mold (Not include manual placement) |

| Available | PP, Nylon, ABS, Acrylic, POM etc. For example: Automobile tail light, Signal light, Fluid reservoir, Container. |

- Series utilize HMI controller.

- Series uses PLC controller.

- PID thermostatic controller, SSR non-contact switch. Micro-temperature compensation ±1℃.

- Temperature difference, pressure difference electronic protector.

- The entire machine uses NC precision processed parts.

- Working kit made with bearing steel SUJ2(RHC62±2) to ensure precision, stability and long operational lifespan.

- Modular mold changing design.

- Strong U shape chassis. Extremely stable during operation with CNC sheet metal and environmentally friendly powder coating.

- Abnormal operation computer monitors circuit function, pneumatic pressure and electrical temperature fool proof capability.

- Hydraulic circuitry utilizes heating and High/Low speed control while jointing. This makes a cleaner and stronger weld joint.

- Operation gate, security light curtain. (Optional)

- Series is CE safety specification certified. (Optional)