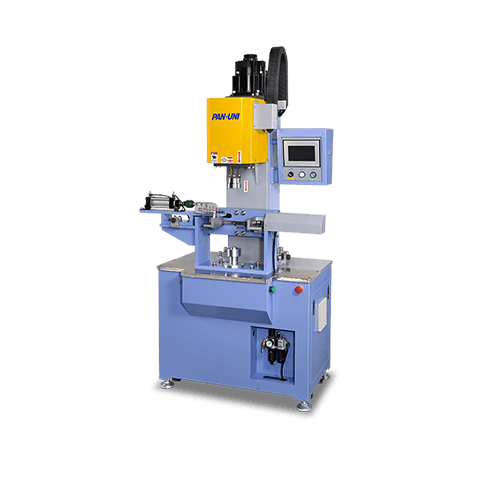

Spin Welding Machine

PU-FS800NC

PU-FS800NC double servo positioning spin welding machine, equipped with center positioning trimming device, high torque Japanese servo system, forward and backward servo drive, rotary processing servo fixed angle (forward and backward high torque ball screw base and servo reducer drive Group). The reinforced H-shaped high-rigidity base is stable and has a long service life. New style optical ruler, fixed distance/signal output device.

Application: After welding, trimming and removing burrs, such as round diameter floats such as PE, PP, nylon, PET, or large round containers.

- Newest design for the spinning base, fast modular mold change system.

- The machine structure is high rigidity steel plate welding, tempering, CNC machining, horizontal, vertical.

- Linear slide rail and ball screw structure.

- HMI combined all adjustment function (abnormal, group, monitoring and other functions)

- It can do the origin reference function of the group spin welding base.

- Option switch of trimming or no trimming mode.

- Central automatic positioning fixture design.

- New type fast modular mold change system.

- Environmentally friendly powder machine and NC machine sheet metal.

| Product Specification | |

|---|---|

| Model | PU-FS800NC |

| Size | L900×W900×H1900mm |

| Weight | 420kg |

| Power | 220V/380V/3∮/2KW |

| Pneumatic | 6kgf/cm2/30ℓ/1minute |

| Capatity | 6-12Sec./1Pcs. Continuous production (Not include manual placement) |

| Available | After welding, trim and remove the burrs of PE, PP, nylon, PET and other round diameter floats or large round containers. |

- Newest design for the spinning base, fast modular mold change system.

- The machine structure is high rigidity steel plate welding, tempering, CNC machining, horizontal, vertical.

- Linear slide rail and ball screw structure.

- HMI combined all adjustment function (abnormal, group, monitoring and other functions)

- It can do the origin reference function of the group spin welding base.

- Option switch of trimming or no trimming mode.

- Central automatic positioning fixture design.

- New type fast modular mold change system.

- Environmentally friendly powder machine and NC machine sheet metal.