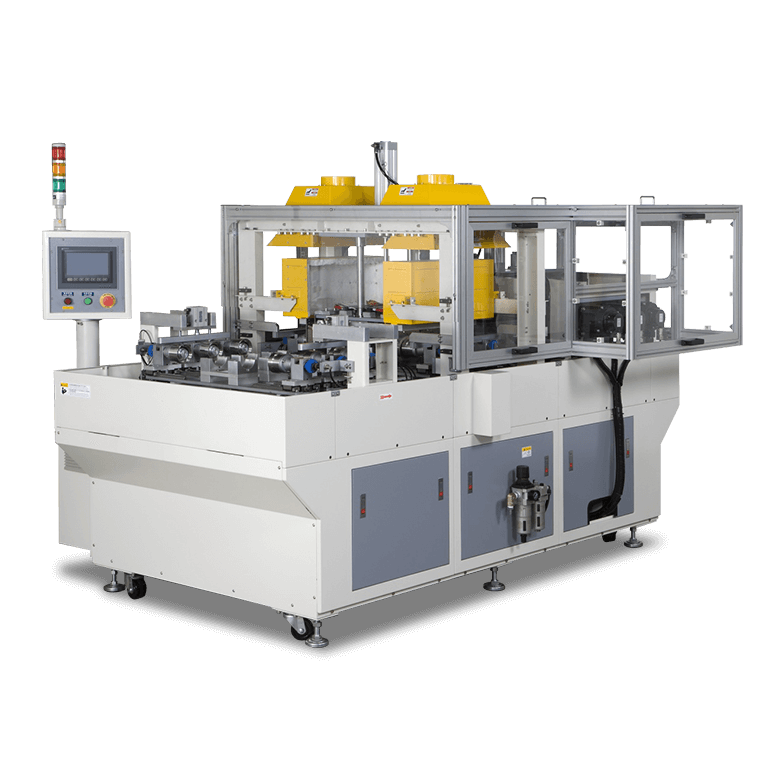

IR Infrared Welding Machine

PU-AIF6983-S IR non-contact infrared plastic welding machine effectively uses heat for welding, which is more energy-saving than traditional hot plate machines. The non-contact welding method has no sticking problems, and the welding surface is smooth and beautiful, and can meet the requirements of water and air tightness.

Application: PP and foldable filter, nylon and foldable filter, 5Micro grade filter end-to-end welding, resin and other plastic products. This equipment adopts full servo operation, manual feeding (3 tube bodies at a time, including 6 end caps), automatic IR infrared welding → automatic end cap combination → automatic return, and the production capacity is increased by 12sec./1pcs.

- All series use HMI, PLC controller.

- Precision indexing action, intermittent conveyor workstations.

- 1mold/3pieces, high efficiency weld processing.

- Feeding, hot welding, combined, discharge, all completely independent operation.

- Working stop point, error 1/16384 accuracy.

- Machining spare part all NC precision processing.

- Design of high temperature thermal radiation mold/low temperature thermal radiation mold.

- Servo welding drive design, combined more accurate.

- Manual material feeding, automatic discharge desing.

Note: 5-micro tube head to tail non-contact welding, 1mold/3pcs. Continuous production.

| Product Specification | |

|---|---|

| Model | PU-AIF6983-S |

| Size | L2050×W2065×H1700mm (Not include control cabinet) |

| Weight | 2500kg |

| Power | 10kw/220v/380V/3∮ |

| Pneumatic | 6kgf/cm2/50ℓ/1minute |

| Capatity | 4-6Pcs./1Minute (Automatic production) |

| Available | PP and folding filter, Nylon and folding filter, 5-micro filter, both end-side welding. |

- All series use HMI, PLC controller.

- Precision indexing action, intermittent conveyor workstations.

- 1mold/3pieces, high efficiency weld processing.

- Feeding, hot welding, combined, discharge, all completely independent operation.

- Working stop point, error 1/16384 accuracy.

- Machining spare part all NC precision processing.

- Design of high temperature thermal radiation mold/low temperature thermal radiation mold.

- Servo welding drive design, combined more accurate.

- Manual material feeding, automatic discharge desing.

Note: 5-micro tube head to tail non-contact welding, 1mold/3pcs. Continuous production.