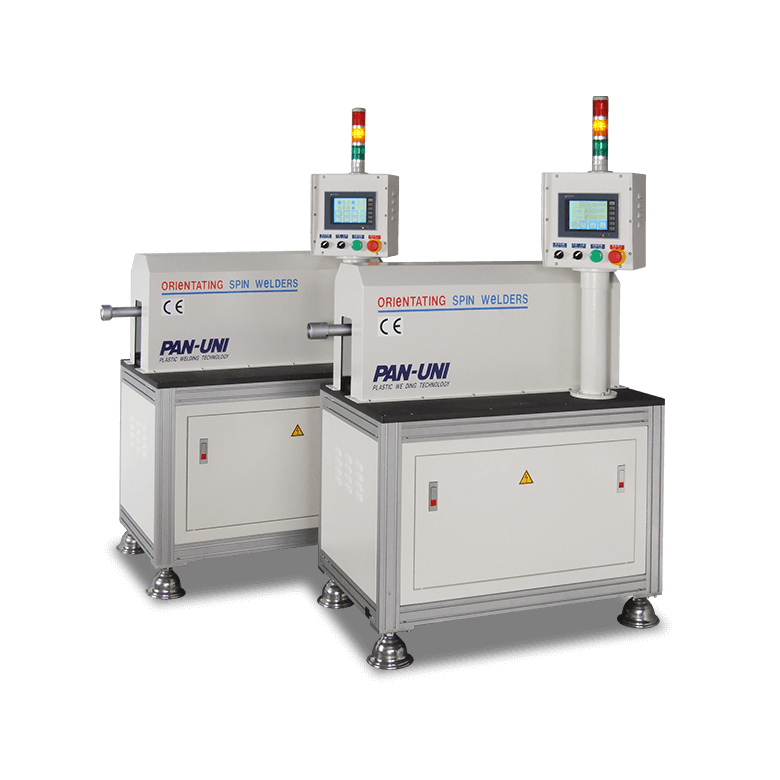

Spin Welding Machine

PU-FS2900L

PU-FS2900L horizontal servo positioning spin welding machine adopts Japanese-made servo motor and driver. Double rotating bases are welded simultaneously, and the length of both ends of the workpiece is adjustable.

Application: Used to connect automation systems with high-precision spinning melting.

- Series uses HMI.

- Series uses PLC controller.

- Japanese YASKAWA high torque servo motor and driver.

- Enlarged chassis column ∮100mm and large upper/lower structure for prevents the torque reaction during startup and rapid stopping.

- Upper/lower guide rod are ∮25mm or larger. To prevents tolerance deviation during heavy spin processing.

- The industry's first design, 2in1 positioning spin welding and trimming function, it can successfully achieve the task of positioning requirements and appearance flash removal (for the trimming model optional).

- Specially designed lower clamp block that adjusts to the position required of the work piece.

- High hardness steel clamp prevent vibration during high-speed spin welding.

- Modular mold change capability.

- Uses NC precision parts, processed and assembled.

- Provide high torque of the motor apparatus, choose from 1.8KW to 15KW. (96N.m【kgf.cm】)

- Conforms to CE safety specification. (Optional)

| Product Specification | |

|---|---|

| Model | PU-FS2900L |

| Size | L1020×W650×H1700mm |

| Weight | 300kg |

| Power | 220V/380V/3∮/20A |

| Pneumatic | 6kgf/cm2/30ℓ/1minute |

| Capatity | 4-6Sec./1Pcs. automatic production |

| Available | Use in conjunction with automated system of RO filter spin welding. |

- Series uses HMI.

- Series uses PLC controller.

- Japanese YASKAWA high torque servo motor and driver.

- Enlarged chassis column ∮100mm and large upper/lower structure for prevents the torque reaction during startup and rapid stopping.

- Upper/lower guide rod are ∮25mm or larger. To prevents tolerance deviation during heavy spin processing.

- The industry's first design, 2in1 positioning spin welding and trimming function, it can successfully achieve the task of positioning requirements and appearance flash removal (for the trimming model optional).

- Specially designed lower clamp block that adjusts to the position required of the work piece.

- High hardness steel clamp prevent vibration during high-speed spin welding.

- Modular mold change capability.

- Uses NC precision parts, processed and assembled.

- Provide high torque of the motor apparatus, choose from 1.8KW to 15KW. (96N.m【kgf.cm】)

- Conforms to CE safety specification. (Optional)